ePad-I Button Panel

Crane control system, excavator control system, etc.

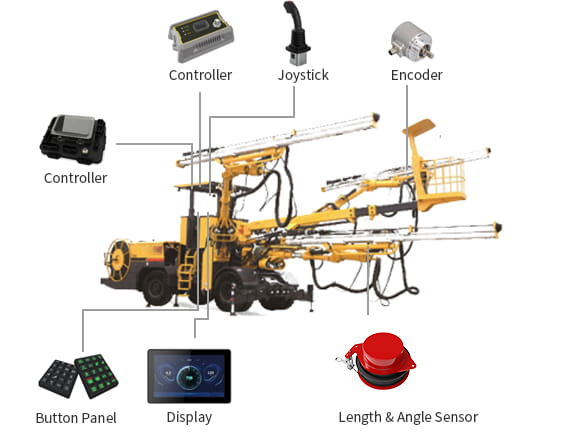

The electric control system of rock drilling jumbo can realize precise hole drilling and positioning functions, the system is more intelligent, multi-functional, sound stability, strong compatibility, the operation safety is greatly enhanced,while enhancing efficiency and reducing damage to the equipment, the wiring harness is easy to check, which has lowered the difficulties for maintenance.

• Precise drilling and positioning: fully computer controlled drilling system, automatic positioning and drilling, precise control of propulsion beam Angle and hole depth, small overcutting.

• Precise drilling and positioning: fully computer controlled drilling system, automatic positioning and drilling, precise control of propulsion beam Angle and hole depth.

• Advanced geological analysis: detect pressure, drilling speed and drill pipe rotation speed and other parameters during construction, analyze and restore geological conditions, and optimize blasting plan.

• Highly penetrated information : automatically record and store drilling logs to provide theoretical basis for later optimization and upgrade.

• Strong adaptability: real-time monitoring of vehicle data, data analysis and processing, automatic adjustment of parameters, so that it can operate stably on different occasions.

• Simple and easy to check: there is no terminal row for the whole vehicle wiring harness, wiring harness is all directly connected, which is really clear.

Shanghai Smart Contol has now become an excellent and reliable product and system provider in the field of automatic control, especially in the field of mobile machinery and outdoor vehicles.

After submitting the contact information, you can get the link to download the file!